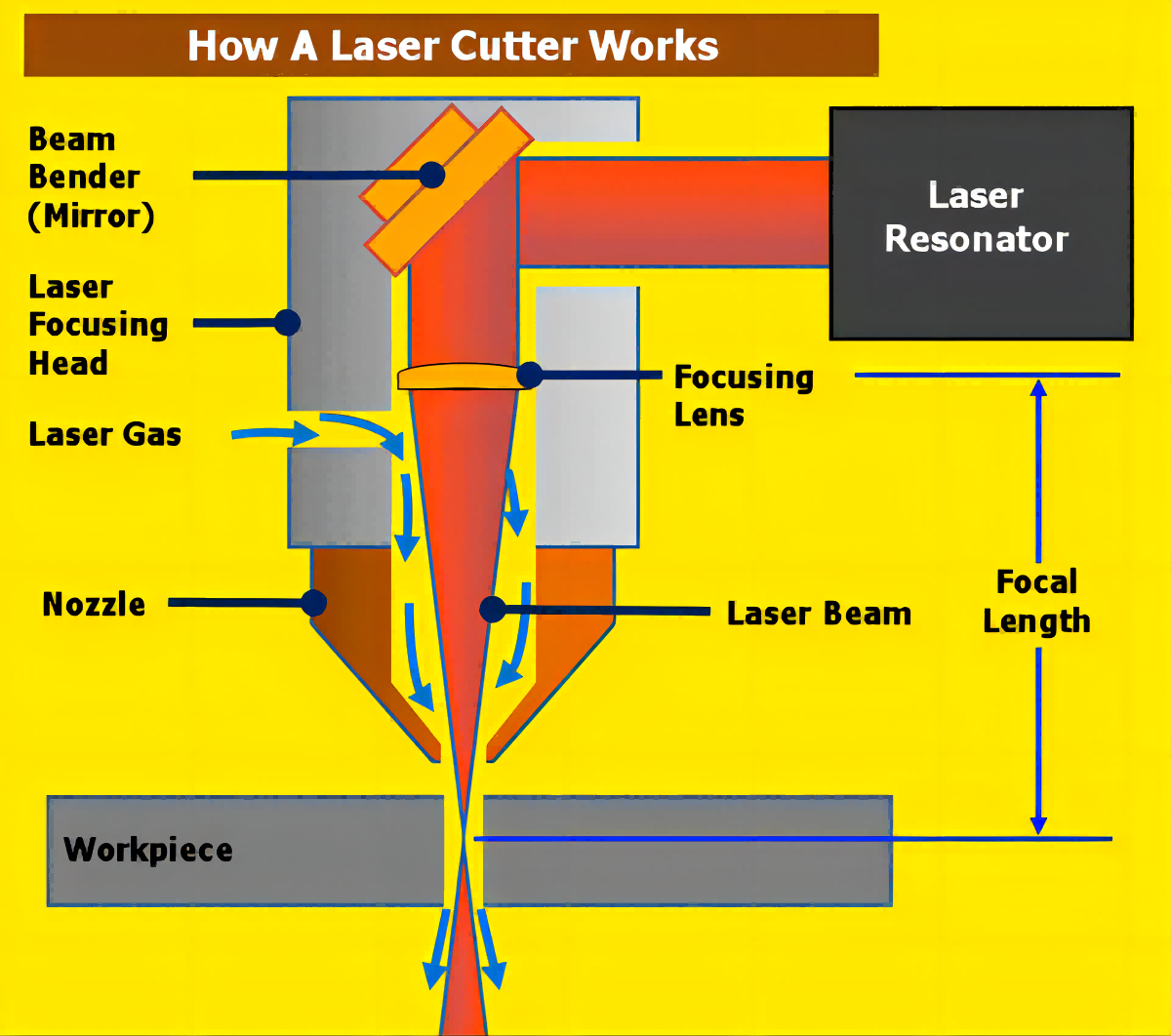

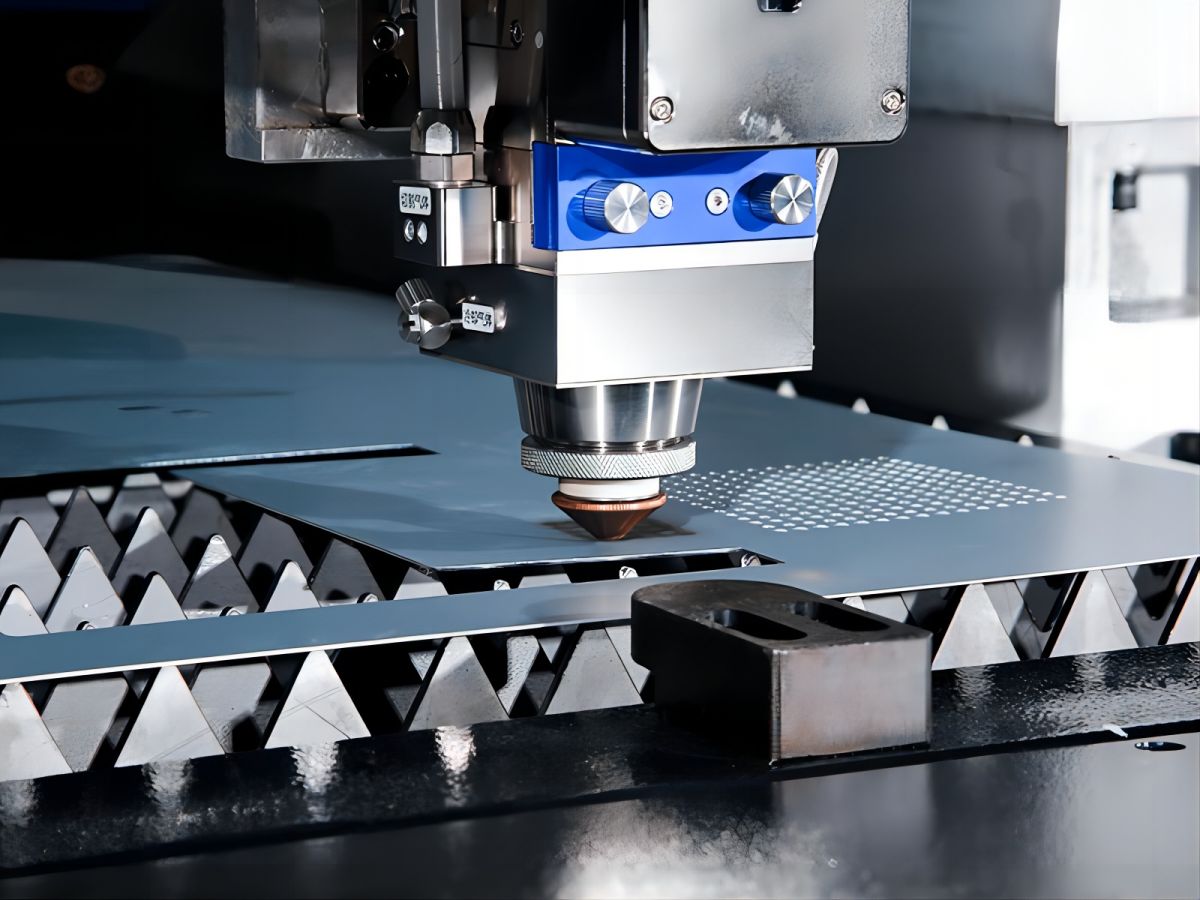

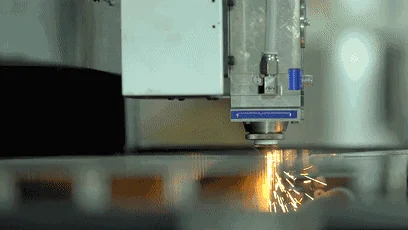

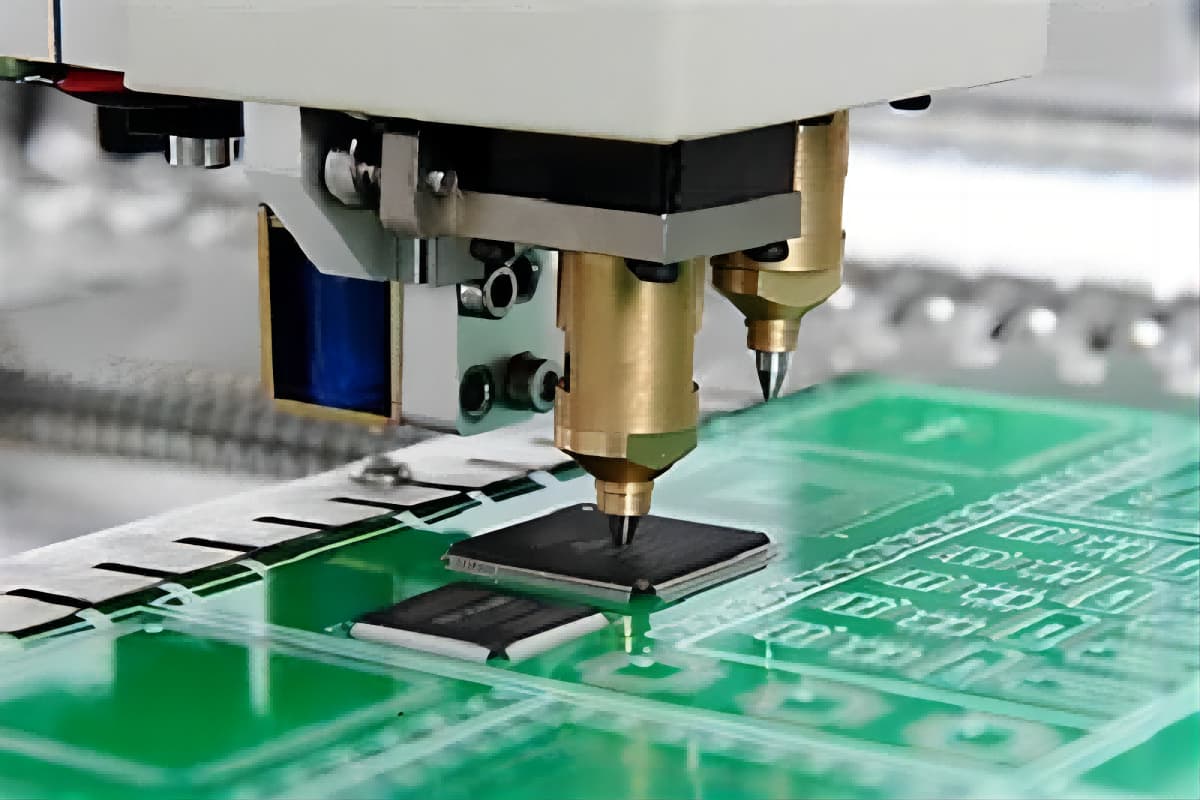

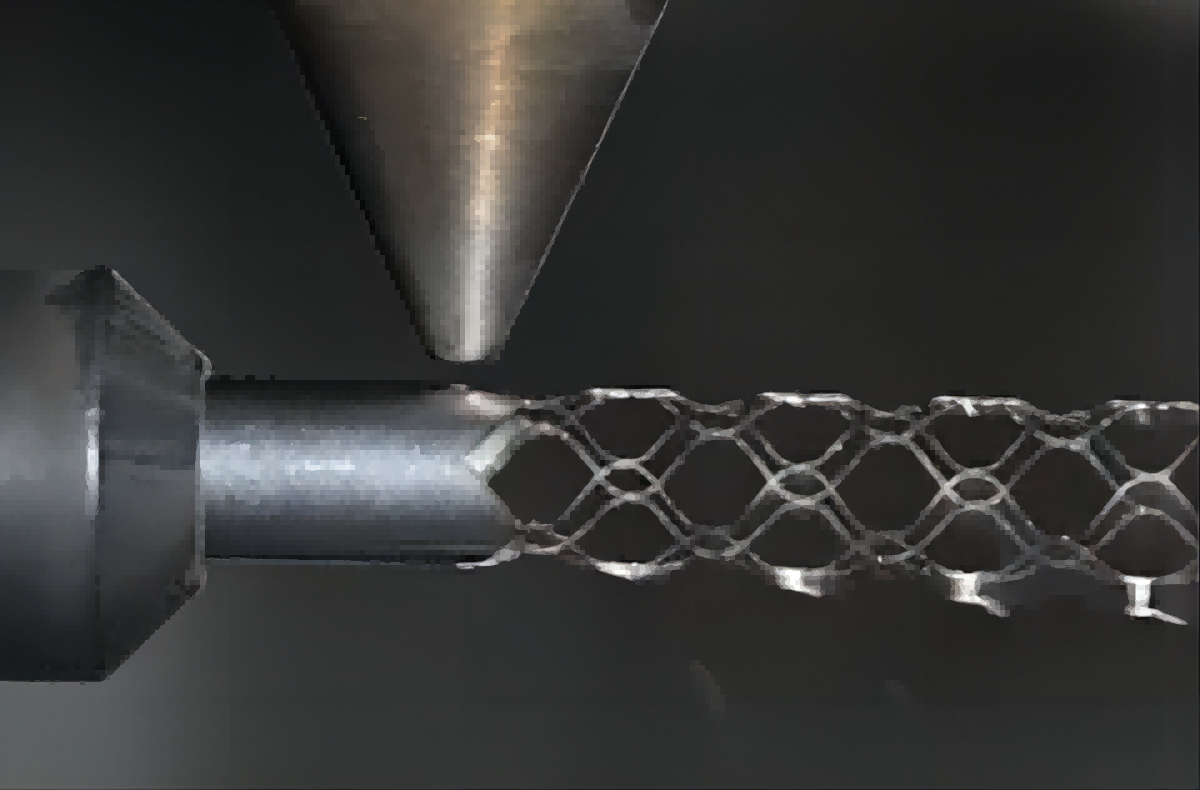

Since the laser cutting machine was invented in the 1960s, its application has widened into automotive, aerospace, electronics and other industries. For example, in automotive fabrication, laser cutting technology is used to produce components, such as body panels, chassis and exhaust systems, to improve efficiency and accuracy. In the aerospace industry, the technology, depending on its premium performance, plays a pivotal role in key components manufacturing, such as aircraft skin, wings and engine blades. In the article, the working principles, basic components, applicable materials, advantages and applications of laser cutting machines so as to deeply introduce this game-changing technology. Here is a short video for you to enjoy the fascinating capabilities of the laser cutting machines: Laser cutting machines utilize high power-density laser beams to irradiate on the workpiece surface, causing the materials to melt, evaporate and undergo chemical reactions.At the same time, the molten materials will blown off by high-speed airflow, and the cutting is finished. Generally, laser cutting can be divided into 4 parts: Typically, a laser cutting machine contains the following components: Lasers: As a light source which provides high power and quality laser beams, lasers commonly include CO2 lasers and fiber lasers. Laser source An optical system: The system, including reflective mirrors, focus lenses and other components, focuses the laser beams precisely on the workpiece surface. Cutting head: It outputs laser beams and cutting gases coaxially and controls their relative movements and position with the workpiece. Cutting head A CNC control system: It controls the moving paths and speed of the cutting head so as to cut automatically. CNC control system An assist system: It includes the cooling system, smoke exhaust system, gas supply system, and other parts to ensure steady and high-efficiency operation. Among these components, lasers as the core factor, directly decides cutting quality and efficiency. By the virtue of high-efficiency and quality, these magic machines is expanding their horizon in industrial manufacturing, boosting laser cutting technology development and industrial development. Take a fiber laser cutting machine as an example: It’s obvious that laser cutting is an intricate process, entailing a laser, an optical system, a CNC control system, a cooling system, and other components. At the same time, the setting of cutting parameters should based on processing materials, thickness, geometric patterns and other factors. Only by understanding their working principles and controlling parameters can we fully leverage the highly efficient, accurate and flexible quality of laser cutting machines. According to the types of lasers, laser cutting machines can be divided into three main categories: CO2 laser cutting machines, fiber laser cutting machines and YAG laser cutting machines. Different machines vary in processing principles, applicable materials and cutting performance. Let’s unveil the secrets of these machines. As one of the widest-applied laser cutting machines, they adopt CO2 gases as working substances and are activated by energy to produce infrared beams with a wavelength of 10.6μm. Besides, CO2 lasers perform well in absorbing non-metals, so that they are suitable for wood, acrylic, glass, paper, fabric, plastic and leather. Pros of CO2 laser cutters: Cons of CO2 laser cutters: Using optical fibers doped with rare earth elements as the gain medium, fiber laser cutters are pumped by semiconductor laser diodes, generating a near-infrared light beam with wavelengths of 1.06 to1.07μm. Lasers in this band have an extremely high absorption rate for metals. Hence fibre laser cutting machines are specifically used for cutting metal materials, especially stainless steel, carbon steel, aluminium, copper, etc. ULFT Dual-use Fiber Laser Cutting Machine Pros of fiber laser cutters: Compared with CO2 laser cutters, fiber laser cutters’ cutting speed for metal materials is 2 to 3 times that of CO2 laser cutters and is hardly affected by material reflectivity. However, they have limitations on non-metal cutting, and the costs are high. The YAG laser cutting machine is a type of solid-state laser cutting equipment based on the yttrium aluminum garnet (YAG) crystal doped with neodymium ions (Nd3+). Its working wavelength is close to that of fiber lasers, also around 1.06μm, hence the YAG laser cutting machine is primarily used for metal cutting as well. Pros of YAG laser cutters: Cons of CO2 laser cutters: Before we dive in, you might want a video to enjoy! In summary, CO2 laser cutting machines are suitable for cutting non-metals, fiber laser cutting machines are more suitable for cutting metals, while YAG laser cutting machines have a moderate cost-performance ratio and can be used as entry-level equipment. Users should weigh their choices based on factors above. With technology advancements, fiber laser cutting machines are expected to replace CO2 laser cutting machines to be the mainstream in more fields. As a highly accurate and efficient processing tool, laser cutting machines are used in many sectors. The article will introduce laser cutting machines’ applications in the automotive, aerospace, electronics, and medical industries. Laser cutting machines, mainly used for precision parts manufacturing in automotive industry, can ensure cutting efficiency and surface quality of precise components. For example, vehicle brake pads and other core components require high-precision cutting so as to make sure their performance and security. Interior parts processing can be also achieved by laser cutters. Interior parts normally entail intricate and high-quality surface processes, which can be met by laser cutters through their flexibility and accuracy. In addition, laser-cutting machines can provide customized design services to meet the demands of various customers. In aerospace, laser cutting machines can be used to manufacture airframe components, which have high requirements on product weight and strength. Laser cutters can ensure material performance is not affected through their high-quality cutting and small heat-affected zones. Engine parts can be produced by laser cutting machines. These components commonly require high precision and complex geometric patterns. The requirements of which can be met by laser cutting machines with high precision and speed. In addition, some materials, such as titanium alloy and nickel-based alloys, that are hard-processed by machines can be handled by laser cutters. Laser cutting machines are mainly used for circuit board cutting. Circuit boards as the main components of electronics, their manufacturing precision and quality directly decide the lifespan and performance of electronics, and thus laser cutters allow for high-efficiency manufacturing for circuit boards. Although heatsinks require intricate patterns and high-quality surface processes, laser cutters can meet the demands depending on their high precision and flexibility. In addition, laser cutting machines can handle the complicated structures of radiators, enhancing their heat dissipation performance. Laser cutting machines are mainly used for all kinds of implants in the medical industry, such as joint replacement and dental implants. Besides, they can also cut complex patterns and shapes from biocompatible materials to ensure the precise fitting of implants and their fine integration with patients. Laser cutting machines can be used to produce surgical instruments. Laser cutting machine’s quality of high-quality and speed can meet the requirements of surgical instruments and ensure their performance and reliability. In addition, customized designs can meet the requirements of various surgeries. The article discusses in detail the working principles, basic components, differences between the three types of laser cutters, and their applications. Laser cutters, by virtue of their high accuracy, speed, and quality, will lead the manufacturing market in the future. If you are interested in specific types and functionalities of laser cutting machines, we invite you to visit our product page. We offer a variety of laser cutting machines, including single-table, dual-table, dual-use, and specialized tube cutting machines. Whether you need to cut metal sheets or tubes, our company has the right solution for you. Hope you find the equipment that best meets your needs. S-Acetyl-L-Glutathione powder, SAG Powder, SAG For Cosmetics Changshu Enzyme Biotechnology Co., Ltd. , https://www.nmnglutathione.comI.Introduction

II.How Do Laser Cutting Machines Work?

Operating principles

Basic components

Laser cutting process step-by-step

III.Types of Laser Cutting Machines

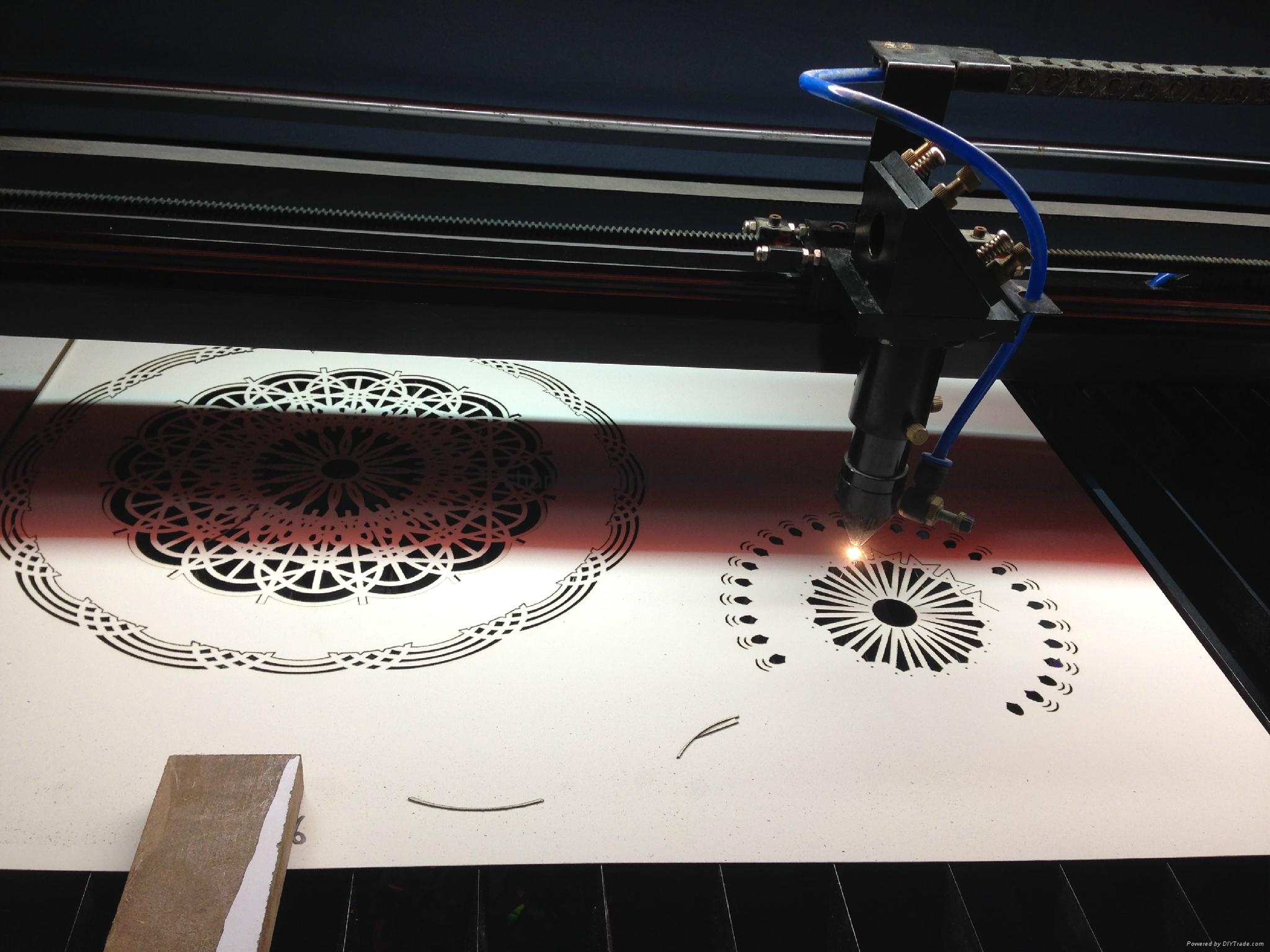

CO2 laser cutters

Fiber laser cutters

YAG laser cutters

Comparison:

Comparison CO2 Laser Cutting Machine Fiber Laser Cutting Machine YAG Laser Cutting Machine Active Medium CO2 gas Rare-earth doped fiber Nd-doped YAG crystal Output Wavelength 10.6μm 1.06μm 1.06μm Suitable Materials Mainly non-metals, such as wood, acrylic, glass, paper, fabric, plastic, leather, etc. Primarily metals, especially highly reflective materials; it can also cut some non-metals Mainly cuts metals, such as aluminum, copper and other non-ferrous metals; can also cut non-metals Cutting Thickness <12mm preferred, slow cutting speed for thick plates <12mm, cutting speed for thin sheets is 2-3 times that of CO2 Low power, only suitable for cutting sheets below 8mm Beam Quality Poor, larger spot size, not suitable for large-area cutting Excellent, small spot size, high power density, can achieve high-precision cutting Good, can achieve high-precision cutting Cutting Precision Medium High High Cutting Speed Medium Fast, several times that of CO2 Slower than fiber, faster than CO2 Electro-Optical Efficiency 10-15% Above 30% 3-5% Power Consumption High Low, about 1/4 of CO2 Higher than fiber Maintenance Cost High, optical components and RF tubes need frequent replacement Low, basically maintenance-free Medium, pump sources need regular replacement Equipment Cost High, about 350,000-1,000,000 CNY Medium, about 200,000-600,000 CNY Low, mature technology, about 100,000-300,000 CNY Operating Cost High, about 20 CNY/hour Low, about 4 CNY/hour Higher than fiber Application Industries Advertising decoration, garment processing, woodworking furniture, crafts, etc. Mainly metal processing such as automotive manufacturing, electronics, precision machinery, etc. Metal engraving and marking, non-metal thin sheet cutting VI.Applications Across Industries

Automotive

Aerospace

Electronics

Medical

V.Conclusion